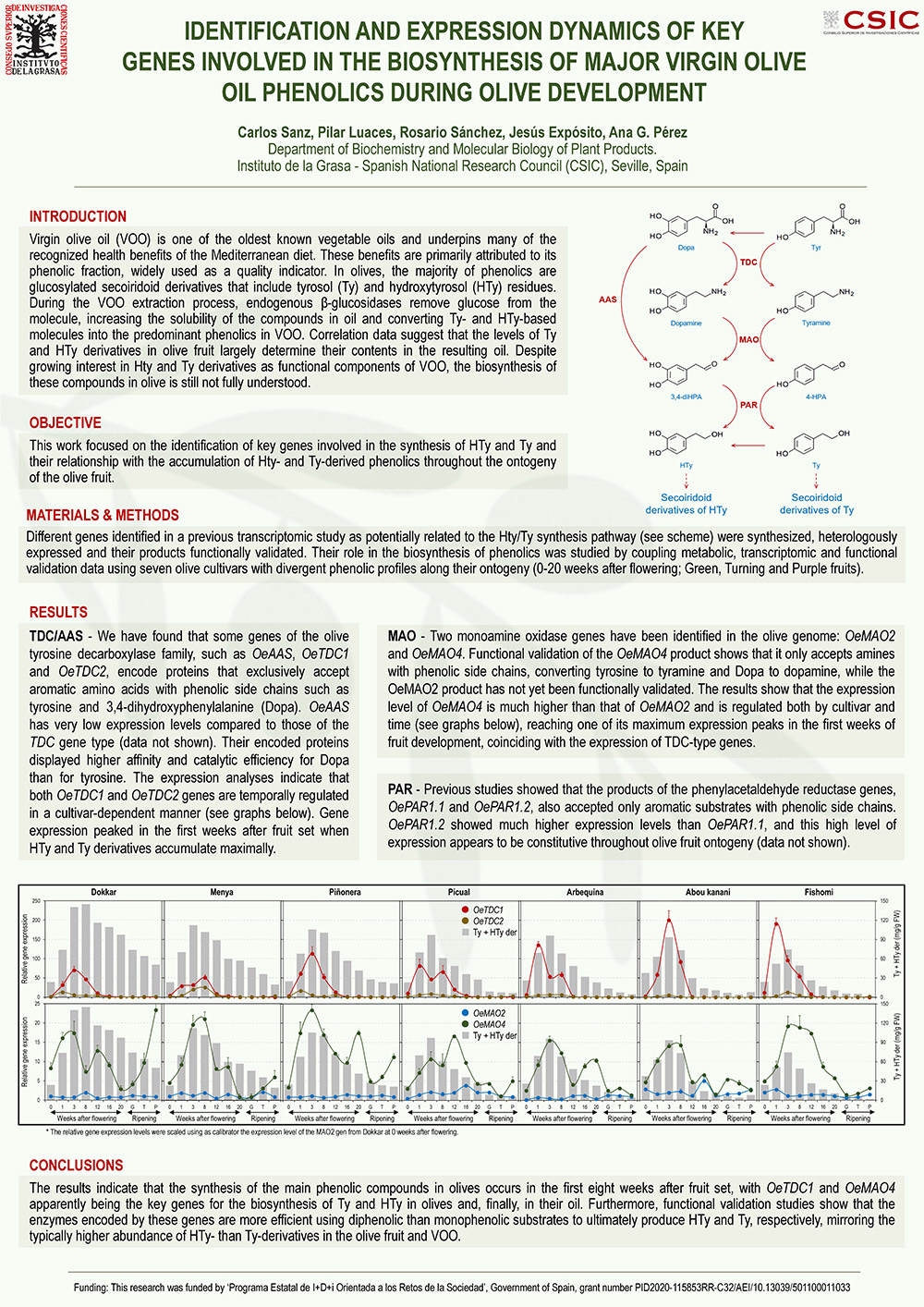

Virgin olive oil (VOO) is one of the oldest known vegetable oils and underpins many of the recognized health benefits of the Mediterranean diet. These benefits are primarily attributed to its phenolic fraction, widely used as a quality indicator. In olives, the majority of phenolics are glucosylated secoiridoid derivatives that include tyrosol (Ty) and hydroxytyrosol (HTy) residues. Correlation data suggest that the levels of Ty and HTy derivatives in olive fruit largely determine their contents in the resulting oil. This work focused on the identification of key genes involved in the synthesis of HTy and Ty and their relationship with the accumulation of Hty- and Ty-derived phenolics throughout the ontogeny of the olive fruit. For this purpose, different genes identified in a previous transcriptomic study as potentially related to the Hty/Ty synthesis pathway were synthesized, heterologously expressed and their products functionally validated. Their role in the biosynthesis of phenolics was studied by coupling metabolic, transcriptomic and functional validation data using seven olive cultivars with divergent phenolic profiles along their ontogeny. The results indicate that the synthesis of the main phenolic compounds in olives occurs in the first eight weeks after fruit set, with OeTDC1 and OeMAO4 apparently being the key genes for the biosynthesis of Ty and HTy in olives and, finally, in their oil. Furthermore, functional validation studies show that the enzymes encoded by these genes are more efficient using diphenolic than monophenolic substrates to ultimately produce HTy and Ty, respectively, mirroring the typically higher abundance of HTy- than Ty-derivatives in the olive fruit and VOO.