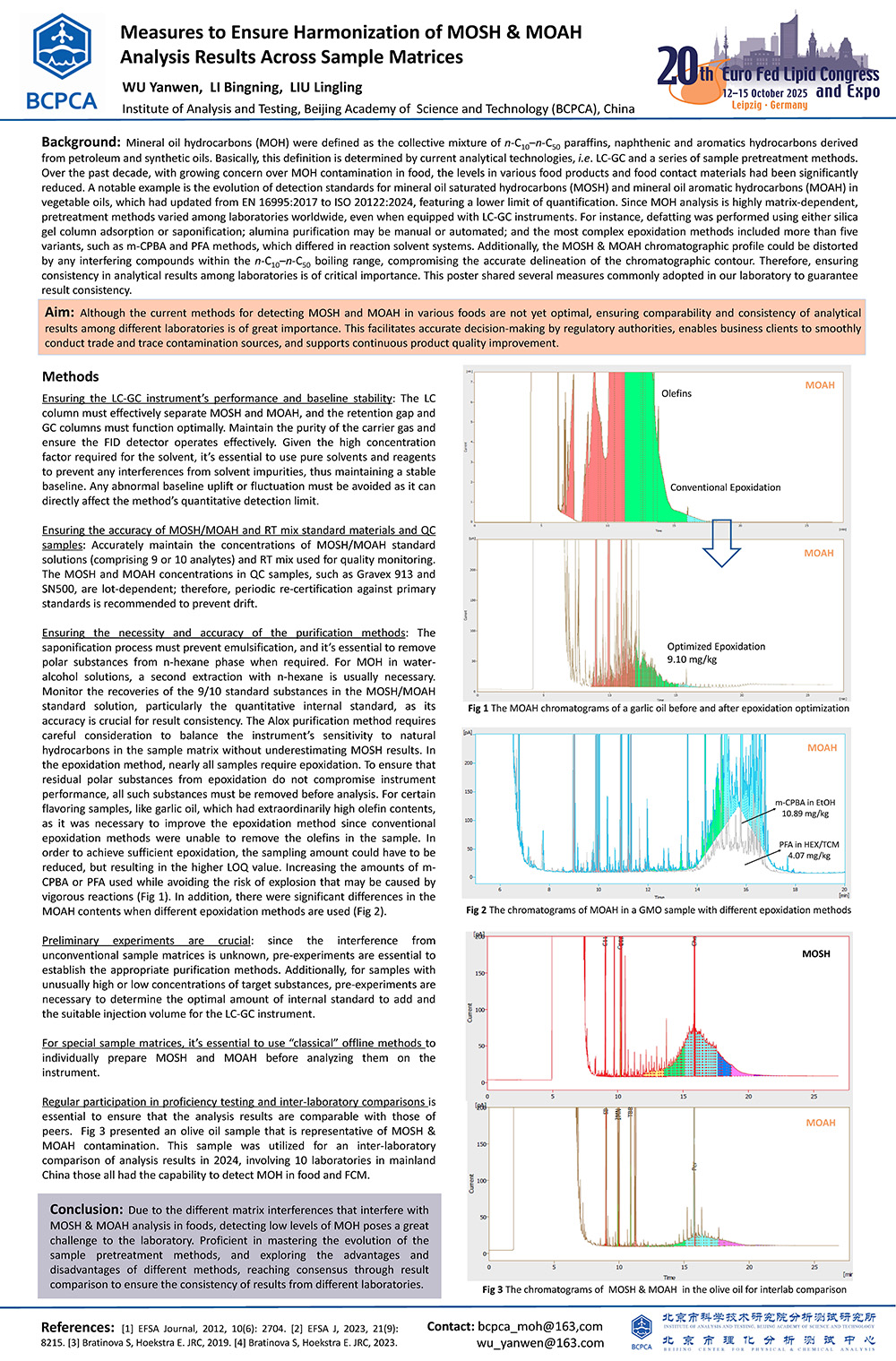

Mineral oil hydrocarbons (MOH) were defined as the collective mixture of n-C10–n-C50 paraffins, naphthenic and aromatics hydrocarbons derived from petroleum and synthetic oils. Basically, this definition is determined by current analytical technologies, i.e. LC-GC and a series of sample pretreatment methods. Over the past decade, with growing concern over MOH contamination in food, the levels in various food products and food contact materials had been significantly reduced. A notable example is the evolution of detection standards for mineral oil saturated hydrocarbons (MOSH) and mineral oil aromatic hydrocarbons (MOAH) in vegetable oils, which had updated from EN 16995:2017 to ISO 20122:2024, featuring a lower limit of quantification. Since MOH analysis is highly matrix-dependent, pretreatment methods varied among laboratories worldwide, even when equipped with LC-GC instruments. For instance, defatting was performed using either silica gel column adsorption or saponification; alumina purification may be manual or automated; and the most complex epoxidation methods included more than five variants, such as m-CPBA and PFA methods, which differed in reaction solvent systems. Additionally, the MOSH & MOAH chromatographic profile could be distorted by any interfering compounds within the n-C10–n-C50 boiling range, compromising the accurate delineation of the chromatographic contour. Therefore, ensuring consistency in analytical results among laboratories is of critical importance. This poster shared several measures commonly adopted in our laboratory to guarantee result consistency.