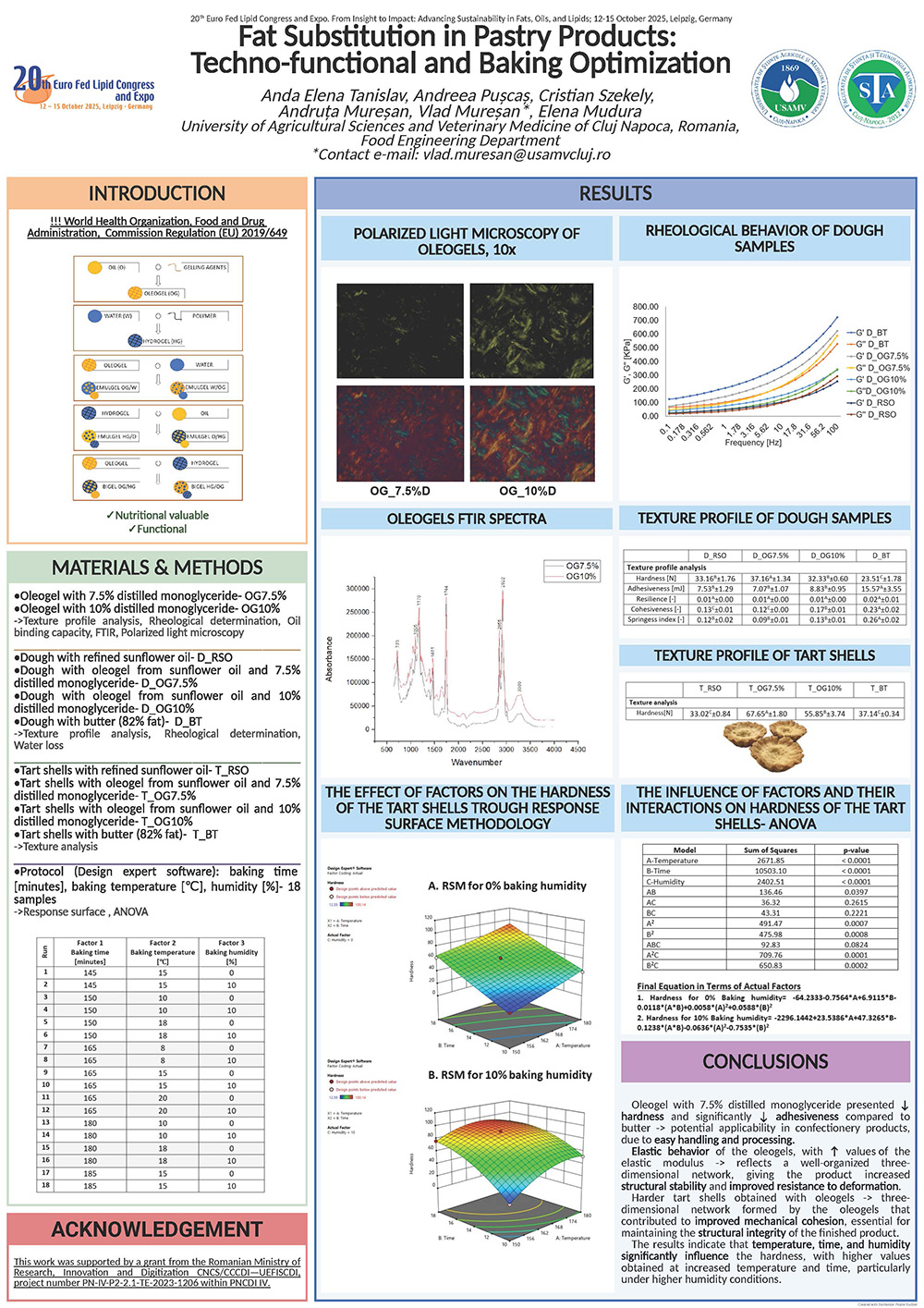

This research aims to investigate the functionality of structured lipids by developing and characterizing oleogels, and subsequently incorporating them into pastry products, as it becomes essential to explore alternatives to saturated and trans fats, in alignment with current nutritional regulations. In this context, two oleogel formulations based on sunflower oil were obtained: OG_7.5%D (containing 7.5% distilled monoglyceride (Dimodan® HP-M) and OG_10%D (containing 10% distilled monoglyceride), and subjected to physicochemical analysis, including texture, rheological behavior, oil-binding capacity, and microstructural evaluation. For comparative analysis, two control samples were included: a negative control using sunflower oil and a positive control using butter (82% fat).

The structured lipids were analyzed in doughs and in the final baked products to understand their effectiveness in fully replacing conventional fats. The sample OG_7.5%D exhibited the lowest hardness value- 13.33 N. In contrast, OG_10%D and the positive control sample showed comparable hardness values- 34.69 N and 43.16 N, suggesting that the liquid oil matrix was sufficiently structured. Regarding the rheological analysis, G’ was higher for OG_10%D, with values gradually increasing with the applied frequency (0.1–10 Hz). Regarding the microscopic analysis, it was observed that increasing the concentration of distilled monoglyceride led to a more homogeneous and dense microstructure. In the context of dough-based semi-finished product analysis, given that the primary objective of incorporating oleogels is to reduce solid fat content while maintaining the functional properties of conventional fats, the dough with OG_7.5%D appears to be the most promising alternative, as supported by its rheological and textural properties. Tart shells prepared with oleogel containing 7.5% distilled monoglyceride exhibited the highest hardness value (67.65 N), followed by those obtained with 10% distilled monoglyceride oleogel (55.85 N), while the control samples prepared with refined oil and butter showed significantly lower hardness values (33.02 N and 37.14 N, respectively). Design-Expert statistic software was used to project the experiment regarding the baking optimization using a combination of 3 factors: baking time [minutes], baking temperature [℃], humidity [%]. The effect of the factors and their interactions on the characteristics of the samples was also studied. Therefore, the use of oleogels as an innovative strategy to fully replace conventional fats can represent a sustainable and efficient direction for the modern food industry.