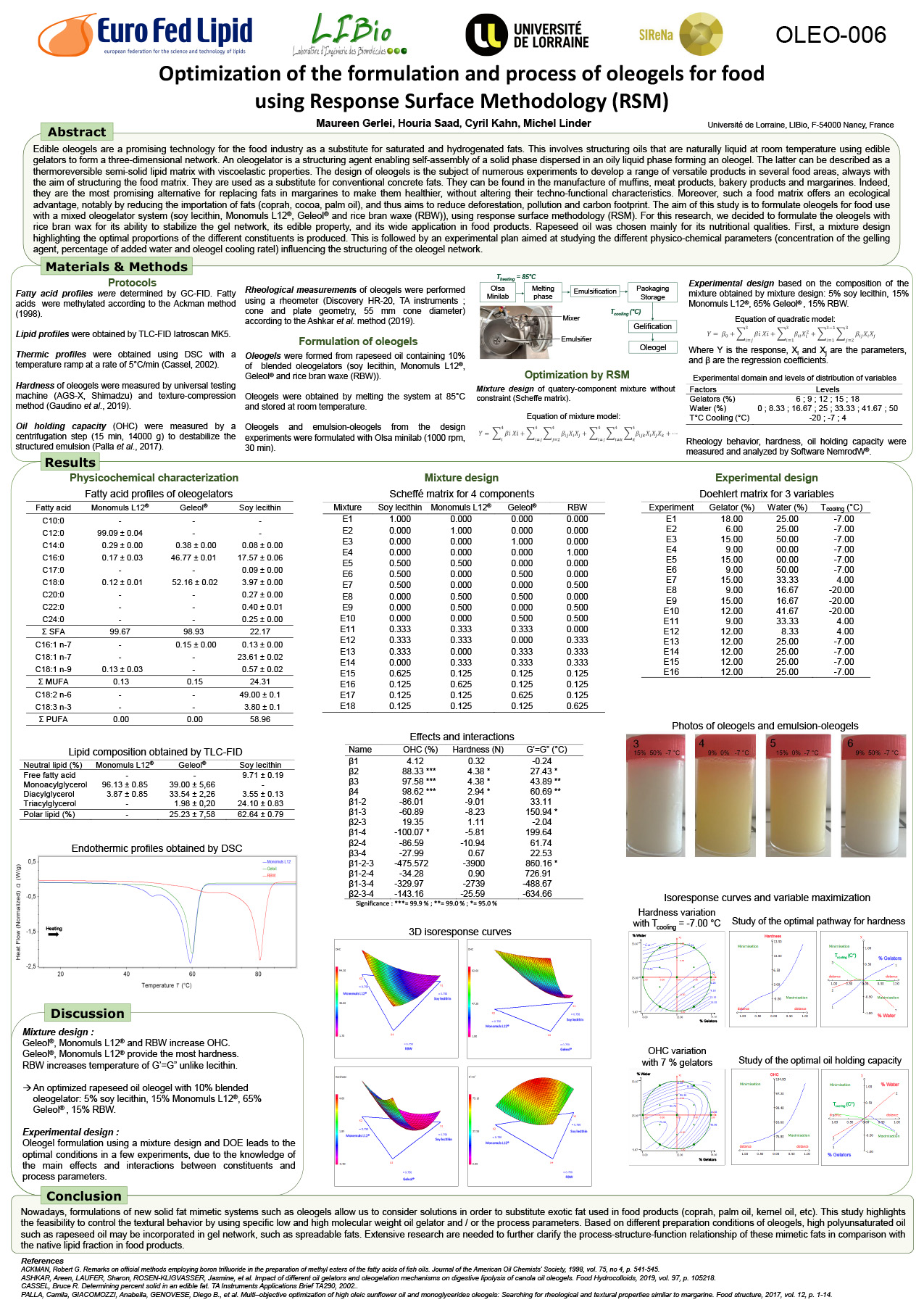

Edible oleogels are a promising technology for the food industry as a substitute for saturated and hydrogenated fats. This involves structuring oils that are naturally liquid at room temperature using edible gelators to form a three-dimensional network. There are also different types of gelators, classifiable as low molecular weight and high molecular weight. An oleogelator is a structuring agent enabling self-assembly of a solid phase dispersed in an oily liquid phase forming an oleogel. The latter can be described as a thermoreversible semi-solid lipid matrix with viscoelastic properties. The design of oleogels is the subject of numerous experiments to develop a range of versatile products in several food areas, always with the aim of structuring the food matrix. They are many used as a substitute for conventional concrete fats. They can be found in the manufacture of muffins, meat products, bakery products and margarines. Indeed, they are the most promising alternative for replacing fats in margarines to make them healthier, without altering their techno-functional characteristics. Moreover, such a food matrix offers an ecological advantage, notably by reducing the importation of concrete fats, and thus aims to reduce deforestation, pollution and carbon footprint. The aim of this study is to formulate oleogels for food use with a mixed gelator system (monoglycerides, diglycerides, lecithin and waxes), using response surface methodology (RSM). The latter is used first to design a mixing plan highlighting the optimal proportions of the various constituents. This is followed by an experimental design to study the various physico-chemical parameters (gelator concentration, percentage of water added and oleogel cooling rate) influencing oleogel network structuring.