Ethyl cellulose (EC), is approved as food additive and is capable alone of forming oleogels in the direct method, presenting potential for the upscaling of oleogelation, the process intended to replace unhealthy or unsustainable fats used in food formulation. The high gelation temperature (>150 ⁰C) of EC leads to oxidation of samples, especially when cold pressed oils, such as beechnut (BK) or sunflower (SF) seed kernel oils are involved.

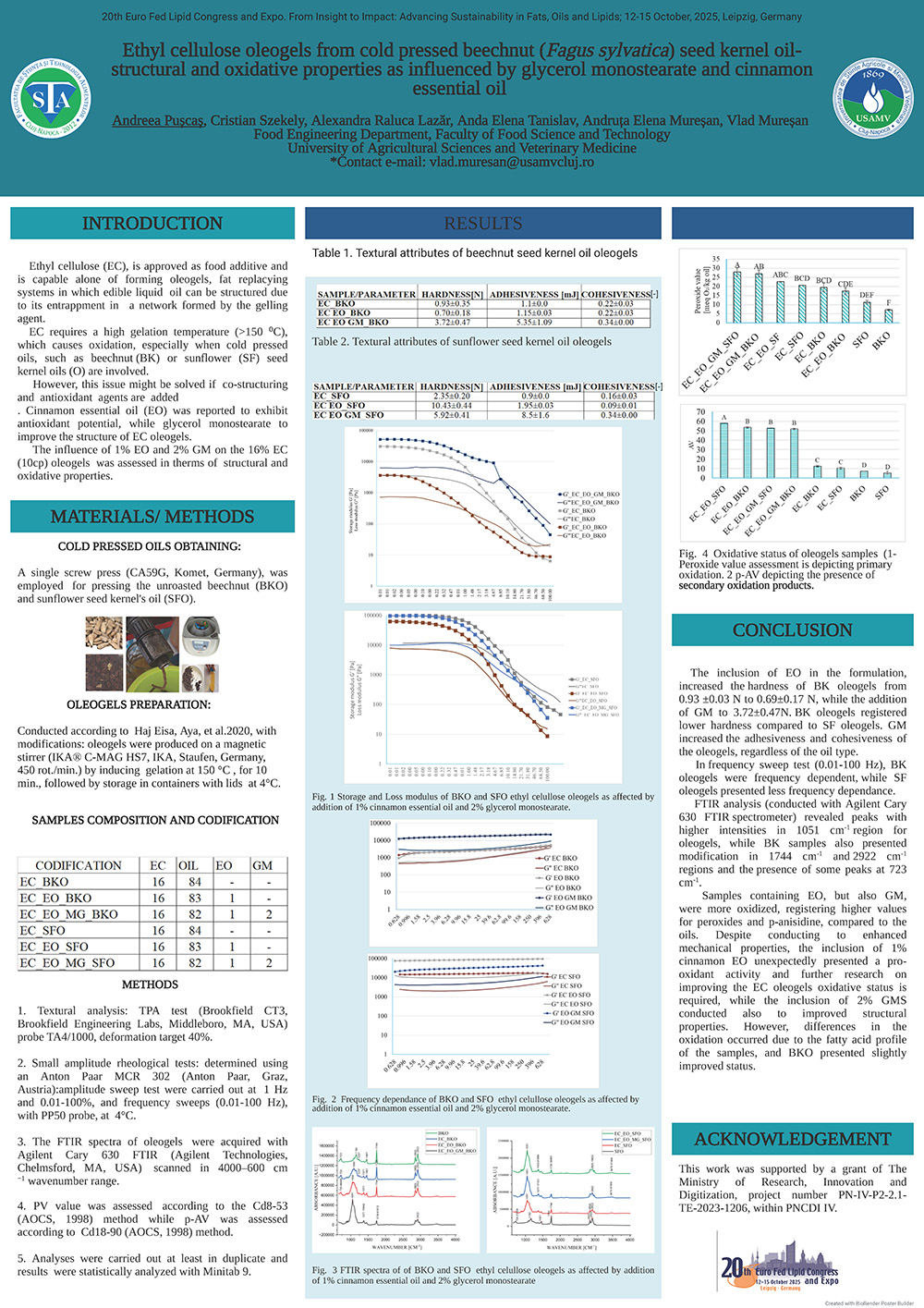

The current study explores the impact of adding 1% cinnamon essential oil (EO) and 2% glycerol monostearate (GM) to the 16%EC (10cp) oleogels in terms of structural (textural, rheological) and oxidative status. The inclusion of EO in the formulation, increased the hardness of BK oleogels from 0.93 ±0.03 N to 0.69±0.17 N, while the addition of GMS to 3.72±0.47N. BK oleogels registered lower hardness compared to SF oleogels. GMS increased the adhesiveness and cohesiveness of the oleogels, regardless of the oil type. In frequency sweep test (0.01-100 Hz), BK oleogels were frequency dependent, except for BK_EO_GM. FTIR analysis (conducted with Agilent Cary 630 FTIR spectrometer) revealed peaks with higher intensities in 1051 cm-1 region for oleogels, while BK samples also presented modification in 1744 cm-1 and 2922 cm-1 regions and the presence of some peaks at 723 cm-1 . Beechnut seed kernel oil registered a PV of 7.12±0.4 meq O₂/kg oil and AV of 7.09±0.13, while for sunflower oil, PV and AV were 10.69 meq O₂/kg oil and 5.41. Samples containing EO, but also GM, were more oxidized, registering higher values for peroxides and p-anisidine, compared to the oils. Despite conducting to enhanced mechanical properties, the inclusion of 1% cinnamon EO unexpectedly presented a pro-oxidant activity and further research on improving the EC oleogels oxidative status is required, while the inclusion of 2% GMS conducted also to improved structural properties.

Acknowledgment: This work was supported by a grant of The Ministry of Research, Innovation and Digitization, project number PN-IV-P2-2.1-TE-2023-1206, within PNCDI IV