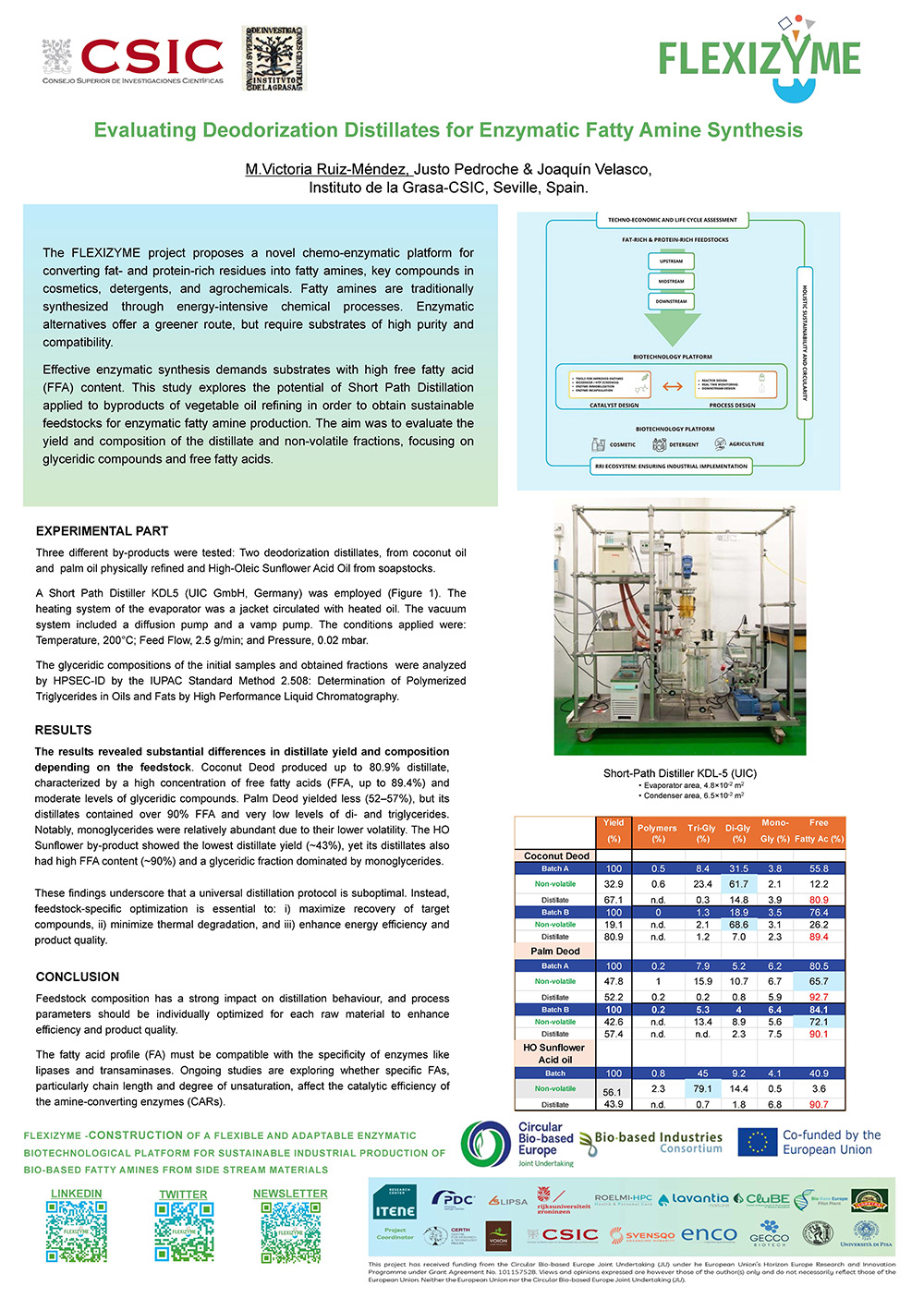

The FLEXIZYME project (CBE-JU EU No. 101157528) proposes a novel chemo-enzymatic platform for converting fat- and protein-rich residues into fatty amines—key compounds in cosmetics, detergents, and agrochemicals. Fatty amines are traditionally synthesized through energy-intensive chemical processes. Enzymatic alternatives offer a greener route, but require substrates of high purity and compatibility This study explores the potential of deodorization distillates (DDs), by-products of vegetable oil refining, as sustainable feedstocks for enzymatic fatty amine production. Effective enzymatic synthesis demands DDs with high free fatty acid (FFA) content. Short path distillation is proposed as a purification step to concentrate FFAs and remove inhibitory compounds, enhancing substrate suitability. Three different DDs were tested as raw materials.

After treatment, all three samples yielded products containing over 90% FFAs, confirming their suitability for enzymatic conversion. The FA profile must align with the specificity of enzymes like lipases and transaminases. Ongoing studies are investigating whether the specific FA profile—particularly chain length and degree of unsaturation—may influence the catalytic efficiency of the amine-converting enzymes (CARs).

With appropriate pretreatment and quality control, deodorization distillates can serve as efficient, sustainable substrates for fatty amine synthesis, supporting circular bioeconomy goals.