Recent reports from FAO show that between 1990 and 2000, France multiplied its production by 50, becoming the European and world leader in hemp seeds (Cannabis sativa L.) production, dethroning China (Xu et al., 2020). Currently in France, the 2015 Energy Transition Act accentuates the priority of producing sustainably within a green economy. This law establishes the circular economy for limiting environmental impact and resource wastage, by exploiting and valorizing waste, now known as co-products. To date, the recovery of co-products (seeds, flowers and aggregates) from hemp cultivation remains limited. The stakes are high, which is why collaborative projects between the various French partners (producers, companies and research centers) have been set up.

BPF-003: Valorization of Peptide and Lipid Fractions of Hemp (Cannabis Sativa L.) Seed Cakes: Combined Action of Pressing and Enzymatic Hydrolysis for the Formulation of a Liposomal Vector

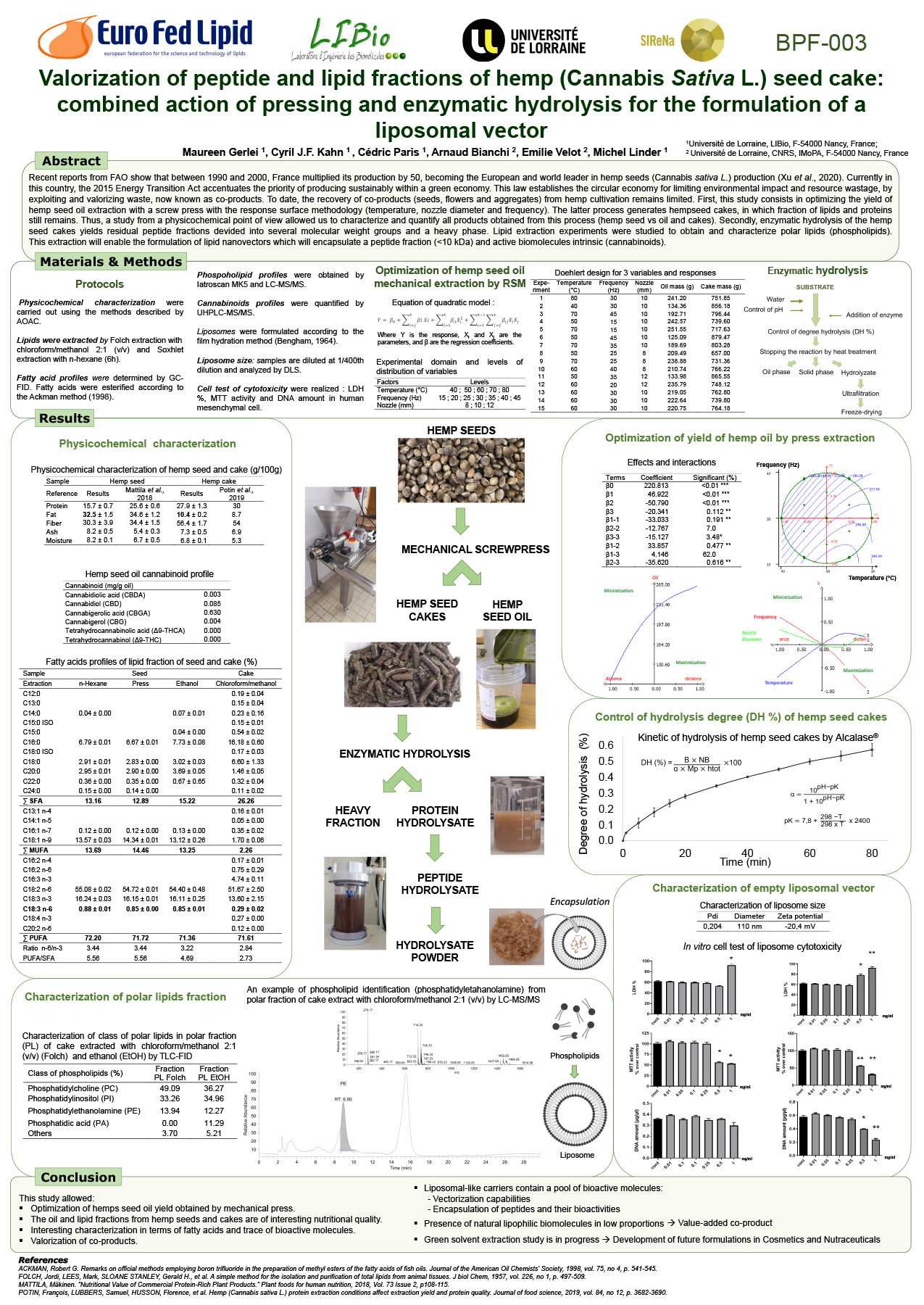

In this study, the first part of the work consists in optimizing the yield of hemp seed oil extraction by mechanical pressing. The latter process generates hempseed cakes, in wich fraction of lipids and proteins still remains. Thus, a study from a physico-chemical point of view allowed us to characterize and quantify all products obtained from this process (hempseed vs oil and cakes).

Secondly, enzymatic hydrolysis of the hempseed cakes yields residual peptide fractions devided into several molecular weight groups by ultrafiltration and a heavy phase. From this phase, lipids extraction/purification experiments were studied to obtain and characterize polar lipids, including phospholipid classes (CPG, TLC-FID, LC-MS/MS). This extraction will enable the formulation of lipid nanovectors which will encapsulate a peptide fraction (<10 kDa) of targeted molecular weight and active biomolecules intrinsic to this plant species (CBGA, CBD).